Surface tension control and surface modification

Are adhesion issues hindering your production? Measure and modify the surface energy of your materials with surface tension test ink and surface treatment equipment.

A convenient overview of our surface tension solutions. Download our e-book

Test inks

Do you need to check the adhesion of your materials?Test pens and inks test the surface energy of plastics, metal, glass or ceramics before committing these fabrics to production.

Surface energy measurement and modification beforehand avoids material failures and time loss during production.

Buy our quick tests now online

Corona equipment

Do you want guaranteed perfect printing quality on various fabrics and in high-speed printing environments?

This can be achieved by increasing the adhesive energy of these materials.

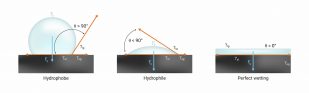

You can alter the surface tension of solid materials with surface treatment equipment such as a corona station or mini corona device. Surface treatment at the beginning or the end of your production line increases the surface treatment of materials for adhesive bonding and flawless printing processes.

Are you having issues with the surface tension energy of solid materials? Talk to our experts for a custom solution!

How we solve adhesion issues

01. ANALYSIS

Do you have issues with the surface energy of your materials, resulting in arduous bonding, printing or labelling? Have you heard of a solution but don’t know whether it’s suitable for your company?

We will discuss your case to pinpoint the exact issue.

02. TESTING

Depending on the issue and solution, we will assist you in implementing the surface treatment equipment in your production line or deliver surface tension test ink samples for you to test.

Either way, we will make sure your production is running at full speed as soon as possible.

03. FOLLOW UP

Are you encountering issues with your equipment or test inks? We are on standby.

Call or email us. We will analyse the problem and provide you with a working solution.

An surface solution, tailored to your industry

Packaging industry

Is static electricity causing efficiency loss during your packaging process? Static issues affect product quality and hinder procedures such as filling, sealing or wrapping. Our antistatic solutions prevent static charges from building up and keep your processes running smoothly.

Plastic Industry

Untreated plastics are prone to electrical accumulation. By neutralising the static charges during processes (liquids) or getting ahead of the problem by altering the chemical composition of your products (additives), you can eliminate unwanted static charges in your operations. This will prevent stickiness, jamming or mis-feeding.

Printing Industry

High-speed printing results in an accumulation of static electricity. This can cause unexpected sheet behaviour, misprinting and fire-hazards during solvent processes. Integrating the right type of equipment in the right place in your production line will discharge static build-up before issues form. The result is a smooth workflow and a safe and contamination-free process..

Automotive & aerospace

Static issues can have a severe effect on automotive procedures such as injection moulding, thermoplastics, blow moulding, paint spraying and so on. Ensuring a dust free and antistatic environment will reduce time and quality loss due to manual intervention. Antistatic solutions also contribute to a safer manufacturing line for operators.

Our surface test and modification solutions

Are you experiencing bad printing or coating quality on your end product due to poor surface adhesion? Is poor adhesion of inks, glues and coatings hindering your production process?

Corona surface treatment stations and portable mini corona devices offer very fast treatment times and optimum adhesion properties.

By modifying the surface energy of metals, plastics, glass or ceramics, these materials are optimised for downstream coating, gluing, painting and printing applications.

- Improved adhesion and wettability properties

- On-the-fly or portable application

- Works on all polymer-based materials

Is bonding between or printing on fabrics such as plastic, metal, glass or ceramic materials a vital part of your production process?

Then you know that poor adhesive energy of your materials results in quality problems or defects. Get ahead of the problem by doing quick surface energy tests with our surface tension test ink beforehand.

How do test inks work? Apply a stroke of ink to the surfaces. If the stroke contracts within 4 seconds, the surface tension energy of the test area is lower than that of the test ink.

If the stroke remains unchanged, the value of the surface tension has been exactly reached or is slightly higher.

The same inks can be used for all measurements, be this on metals, plastics or other materials. They can be used for both production and laboratory purposes.

- Easy assessment of surface tension

- Result within seconds

- All materials, one ink

- Budget-friendly